Instant payments

No chargebacks

Lower transaction fees

Seamless experience

Increase conversions

with Open Banking

Our advanced technology and secure systems provide a safe and reliable way to transfer funds, allowing you to benefit from reduced processing times and improved efficiency.

Eliminate chargebacks

Reduce cost

Instant settlements

Tired of paying high Card fees?

Join payments evolution with us. Accept bank payments that are settled in seconds.

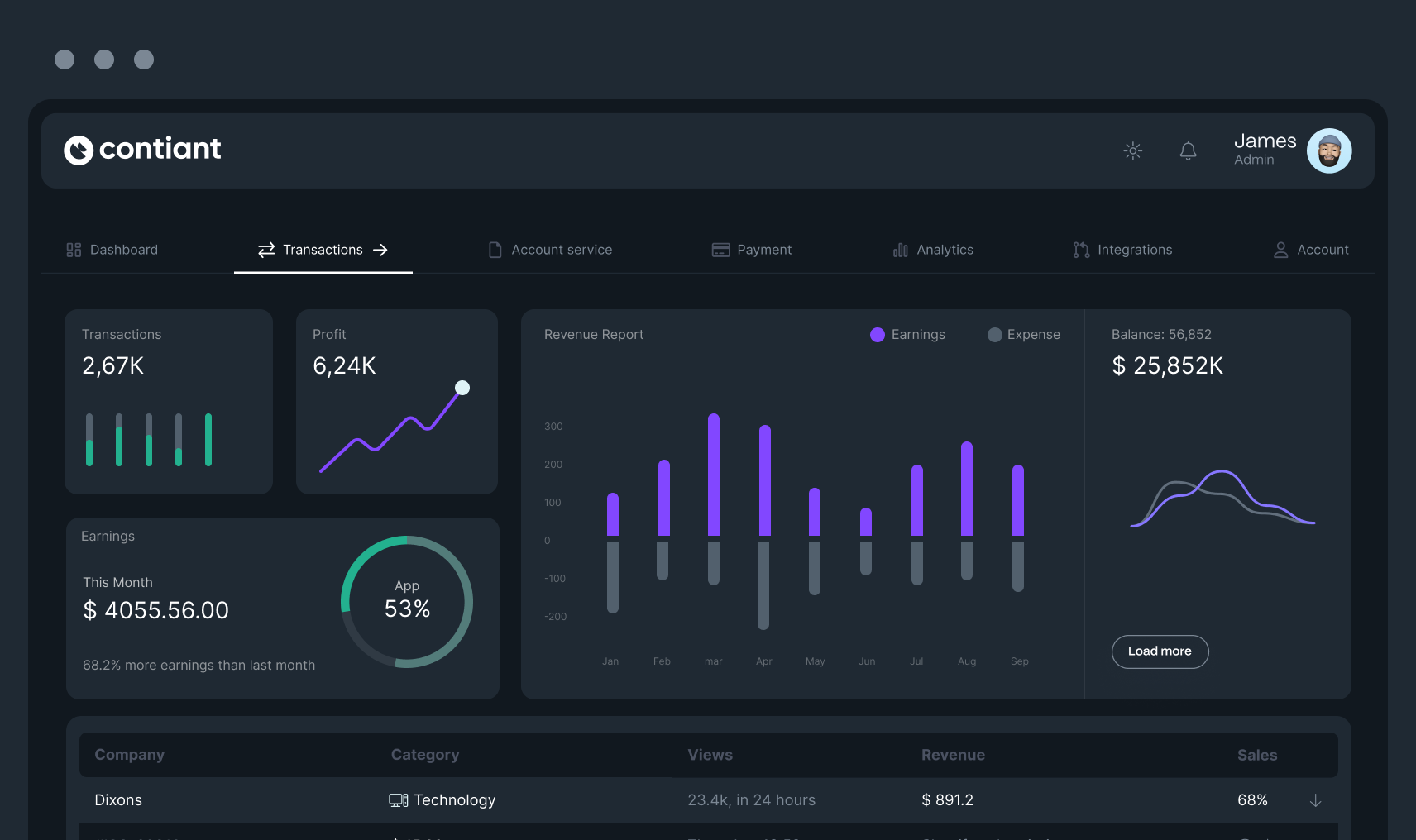

One payments power grid

Unlock the power of banking data

Balance

Transactions

Bank account details

Conversion

Benefit from our fully customizable payment form created to convert and retain your customers. You are in full control. Form the colors to the layout to the payments journey.

Payment way with

Balance

Contiant

Merchant

Turnkey API solution designed to scale your business

Built in mind for developers

Go from idea to implementation quickly with robust, bank-grade APIs. Our documentation, sample data and code snippets provide developers with powerful tools to launch your next innovation.

All your transactions and data in one place

Reconcile and track transactions from initiation to settlement. Create an account to start accepting payments today so you can focus on growing your business while we take care of the payments.

Payments intelligence

Reporting at its best.

See payments data how you like it when you want it. Analyse and make decisions.

Payment evolution for every industry

Lending

iGaming and Forex

Crypto

Wealth management

PSPs and EMIs

eCommerce

Start building today

Get in touch to learn how our open banking solution can increase efficiency and speed for your business.